Engine Valve Guides: A Comprehensive Overview

Valve guides are crucial engine components, ensuring proper valve movement and sealing; their condition directly impacts performance and longevity, requiring diligent maintenance.

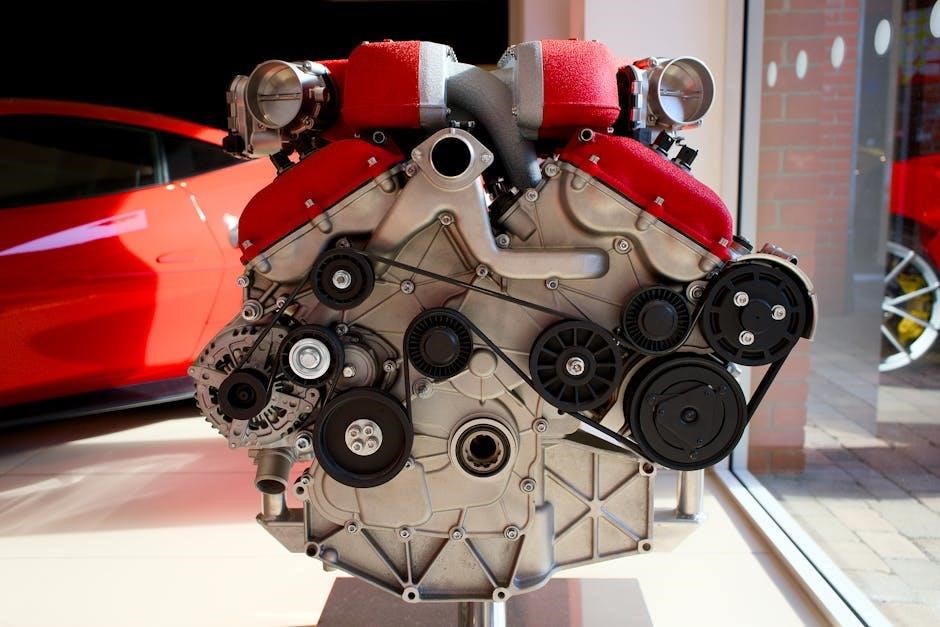

Valve guides represent a fundamental aspect of internal combustion engine functionality, often overlooked yet critically important for optimal performance and engine health; These cylindrical components are precisely installed within the cylinder head, serving as a low-friction surface for the valve stems to move within.

Their primary role is to maintain correct valve alignment, ensuring the valve seats properly against the valve face to create a tight seal during combustion. Without properly functioning valve guides, engines can suffer from reduced compression, increased oil consumption, and ultimately, significant power loss. Understanding their function, materials, and potential failure points is essential for any mechanic or engine enthusiast seeking to maximize engine lifespan and efficiency.

What is a Valve Guide?

A valve guide is a cylindrical insert pressed into the cylinder head, providing a precise and durable pathway for the valve stem’s reciprocating motion. Typically manufactured from materials like cast iron, powdered metal, or bronze, these guides are designed to withstand high temperatures and constant friction.

They aren’t a solid, one-piece component with the head; instead, they are installed to offer a replaceable wear surface. The inner diameter of the guide is carefully machined to match the valve stem diameter, maintaining alignment and preventing side loading. Proper fit is crucial – too tight, and it causes friction; too loose, and it leads to valve wobble and potential damage, impacting engine sealing and efficiency.

Function of Valve Guides in an Engine

Valve guides perform several critical functions within an internal combustion engine. Primarily, they accurately direct the valve’s movement as it opens and closes, ensuring a precise seal against the valve seat. This precise guidance is vital for maintaining optimal combustion chamber pressure and preventing exhaust or intake gas leakage.

Furthermore, valve guides help dissipate heat from the valve head, protecting the valve and valve seat from thermal stress. They also minimize valve stem wobble, reducing wear on both the valve stem and the valve seat. Without properly functioning guides, valve sealing suffers, leading to reduced engine compression, increased oil consumption, and ultimately, diminished engine performance and potential damage.

Materials Used in Valve Guide Construction

Valve guides are commonly crafted from cast iron, powdered metal, or bronze, each offering unique properties regarding wear resistance and heat dissipation.

Cast Iron Valve Guides

Cast iron valve guides represent a traditional and cost-effective choice for many engine applications. They offer good wear resistance, particularly when properly lubricated, and possess inherent damping characteristics that help reduce valve train noise. However, standard cast iron is susceptible to wear from abrasive particles and can exhibit lower strength compared to more modern materials.

Chilled cast iron, a variation, enhances surface hardness and wear resistance through a specialized cooling process. Despite their benefits, cast iron guides may not be ideal for high-performance engines experiencing extreme temperatures or stresses. Regular oil changes and effective air filtration are vital to prolonging the life of cast iron valve guides by minimizing abrasive wear and maintaining proper lubrication. Careful attention to valve bridge settings is also crucial for optimal performance and longevity.

Powdered Metal Valve Guides

Powdered metal (PM) valve guides are manufactured through a process of compacting metal powders, offering a cost-effective alternative with good dimensional accuracy and consistent quality. These guides typically utilize iron-based alloys, often incorporating specific additives to enhance wear resistance and lubricity. PM guides are generally self-lubricating due to their inherent porosity, which allows oil to permeate and provide continuous lubrication during operation.

While not as strong as some other materials, PM valve guides are suitable for a wide range of engine applications, particularly where weight reduction is a consideration. Proper installation is crucial, as dimensional accuracy is key to their performance. Maintaining a clean air filter is paramount to prevent abrasive particle damage, extending the lifespan of these guides and ensuring optimal engine function.

Bronze Valve Guides

Bronze valve guides represent a premium option, renowned for their exceptional wear resistance and inherent lubricity. Typically crafted from alloys containing copper, tin, and other elements, bronze guides excel in high-performance and heavy-duty applications. Their composition allows them to operate effectively with minimal lubrication, reducing reliance on oil film and minimizing potential sticking issues.

However, bronze guides are generally more expensive than alternatives like cast iron or powdered metal. They also exhibit lower thermal conductivity, potentially leading to localized heat buildup. Careful consideration of engine operating conditions and valve speeds is essential when selecting bronze guides. Proper installation and maintaining a clean intake system are vital to maximize their longevity and performance.

Chilled Cast Iron Valve Guides

Chilled cast iron valve guides offer a balance of durability and cost-effectiveness, making them a common choice for many engine applications. The “chilling” process rapidly cools the molten iron during casting, creating a hard, wear-resistant surface layer. This hardened layer significantly improves the guide’s ability to withstand the constant friction from the valve stem.

While not as inherently lubricious as bronze, chilled cast iron guides perform well with proper lubrication. They are generally more affordable than bronze or powdered metal options. However, they can be susceptible to cracking under extreme thermal stress or impact. Careful installation and avoiding excessive force during valve stem movement are crucial for maximizing their service life and preventing premature failure.

Valve Guide Wear and Failure

Valve guide deterioration stems from factors like wear, foreign particles, and improper maintenance, leading to excessive clearance and impacting engine efficiency and performance.

Causes of Valve Guide Wear

Several factors contribute to valve guide wear over time. A primary cause is simply the constant reciprocating motion of the valve stem within the guide, gradually eroding the material. This is exacerbated by inadequate lubrication or contaminated oil, allowing metal-on-metal contact.

Improperly adjusted or maintained valve bridges significantly increase wear, as they can induce side loading on the valve stem and guide. The influx of foreign particles – dust, dirt, or combustion byproducts – acts as an abrasive, accelerating wear.

Furthermore, excessive reaming during repair procedures, intended to smooth the guide bore, can remove too much material, creating excessive clearance. Finally, poor air filtration allows abrasive particles into the engine, contributing to overall wear, including that of the valve guides.

Excessive Valve Guide Clearance – Consequences

Excessive valve guide clearance leads to a cascade of negative effects on engine performance. The most immediate consequence is a reduction in valve control, allowing the valve to wobble or vibrate during operation. This compromises the valve-to-seat seal, resulting in combustion gas leakage – known as blow-by – and a subsequent loss of compression.

This blow-by not only reduces power output but also introduces hot, unburnt gases into the exhaust stream, impacting emissions. Furthermore, the valve wobble accelerates valve seat wear, creating a vicious cycle of deterioration.

Increased oil consumption is another common symptom, as oil can seep past the worn guide and into the combustion chamber, leading to potential fouling of spark plugs and catalytic converter damage.

Foreign Particle Damage

Foreign particle intrusion represents a significant threat to valve guide integrity. Debris, such as carbon buildup, dirt, or even metal fragments from other engine components, can become lodged between the valve stem and the guide’s inner surface. This abrasive action causes scoring and wear, rapidly accelerating guide deterioration.

Even seemingly minor particles can inflict substantial damage over time, particularly under the high-stress conditions of engine operation. The resulting surface imperfections disrupt the smooth sliding motion of the valve stem, exacerbating wear and potentially leading to valve sticking.

This damage isn’t always immediately apparent during visual inspections, making preventative maintenance, like clean air filtration, crucial for minimizing the risk of particle-induced valve guide failure.

Improper Valve Bridge Settings & Maintenance

Improper valve bridge settings, or a lack of consistent maintenance, directly contribute to accelerated valve guide wear. Incorrect adjustments can induce excessive side loading on the valve stem, forcing it to bind within the guide. This binding creates friction and uneven wear patterns, compromising the guide’s internal diameter;

Regular valve adjustments are essential to ensure proper valve operation and minimize stress on the guides. Neglecting these adjustments allows misalignment to develop, leading to premature guide failure. Consistent inspection and lubrication of valve train components are also vital.

Failure to address these issues results in increased wear, potentially causing valve sticking and ultimately impacting engine performance and reliability.

Symptoms of Worn Valve Guides

Worn valve guides manifest as increased oil consumption, valve seat wear, and diminished engine compression, signaling potential internal damage and reduced efficiency.

Engine Oil Consumption

Excessive engine oil consumption is a prominent symptom of worn valve guides. As the valve guides wear, the clearance between the valve stem and the guide increases. This allows oil to seep past the valve stem seals and into the combustion chamber, where it’s burned during the combustion process.

This oil burning leads to a noticeable drop in oil levels, requiring frequent top-ups. Blueish smoke emanating from the exhaust pipe, particularly during acceleration, is another telltale sign. The amount of oil consumed can vary depending on the severity of the wear, but consistent and increasing oil consumption should prompt a thorough inspection of the valve guides. Ignoring this symptom can lead to more significant engine damage over time.

Valve Seat Wear

Worn valve guides contribute significantly to accelerated valve seat wear. Excessive valve guide clearance causes the valve to wobble or move laterally during operation. This unsteady movement prevents the valve from sealing properly against the valve seat, leading to uneven contact and increased friction.

Over time, this uneven contact causes pitting, erosion, and eventual wear of the valve seat. A compromised valve seat reduces the engine’s compression, impacting performance and fuel efficiency. It’s common to observe intake valve seat wear when the air filter is improperly fitted or excessively dirty, allowing abrasive particles to enter the engine. Addressing worn valve guides is crucial to prevent further valve seat damage and maintain optimal engine function.

Poor Engine Compression

Worn valve guides directly lead to poor engine compression. Excessive valve guide clearance allows valves to not fully seat, creating a gap through which combustion gases can escape. This leakage reduces the cylinder’s ability to build pressure during the compression stroke, diminishing overall engine power and efficiency.

The effective sealing of a valve and valve seat, governed by the guide’s precision, is compromised with wear. Consequently, the influx of hot gases past the valve reduces the force applied to the piston during the power stroke. This results in noticeable performance issues, including reduced acceleration and increased fuel consumption. Addressing worn valve guides is vital for restoring optimal compression and engine performance.

Valve Guide Inspection and Measurement

Valve guide inspection involves visual checks for wear and utilizing specialized measuring tools to accurately determine valve stem-to-guide clearance levels.

Visual Inspection for Wear

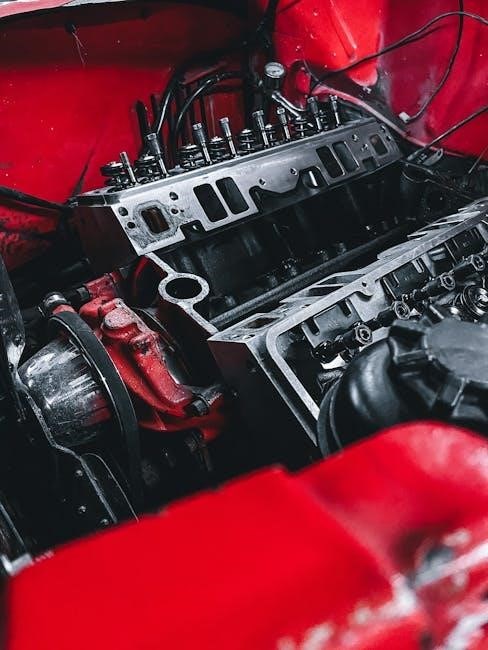

A thorough visual inspection is the first step in assessing valve guide condition. Begin by carefully examining the outer surface of the guide for any signs of scoring, pitting, or erosion. Look closely at the valve stem bore for discoloration, which can indicate excessive heat or a lack of lubrication.

Pay particular attention to the areas of the guide that are most susceptible to wear, such as the lower portion where it contacts the valve stem during operation. Check for any evidence of valve stem movement or “rocking” within the guide, as this is a clear indication of excessive clearance.

Also, inspect the valve seat area around the guide for any signs of damage or wear, as these components often wear together. Any visible damage warrants further investigation and measurement to determine the extent of the problem.

Using a Valve Guide Measuring Tool

Employing a specialized valve guide measuring tool provides precise clearance data. These tools typically consist of a series of graduated pins or sleeves inserted into the guide bore. Select the pin that snugly fits – minimal play is ideal.

The tool’s reading indicates the internal diameter of the guide. Compare this measurement to the valve stem diameter; the difference reveals the clearance. Accurate readings require a clean guide bore and properly calibrated tool.

Ensure the tool is inserted straight and fully seated to avoid inaccurate results. Multiple measurements at different points within the guide bore are recommended to identify any ovality or taper. Document all readings for comparison against manufacturer specifications.

Checking Valve Stem to Guide Clearance

Accurate valve stem to guide clearance assessment is vital for optimal engine function. Excessive clearance permits valve wobble, leading to seat wear and reduced sealing efficiency. Insufficient clearance causes valve binding and potential damage to both valve and guide.

After measuring the guide’s inner diameter and the valve stem’s outer diameter, calculate the difference. Manufacturer specifications dictate acceptable clearance ranges, typically a few thousandths of an inch.

Inspect the entire valve stem length for consistent clearance; variations indicate guide wear or stem bending. Use a dial indicator to measure valve wobble within the guide, confirming proper alignment and minimal play.

Valve Guide Replacement and Repair

Valve guide repair involves removal, reaming, or honing; however, significant wear often necessitates complete replacement for restoring proper valve alignment and sealing.

Valve Guide Removal Techniques

Removing worn valve guides requires precision to avoid cylinder head damage. Several techniques exist, each suited to different situations and available tooling. A common method involves utilizing a valve guide driver, a specialized tool that presses the guide out from the valve seat side of the head.

Prior to removal, thoroughly clean the area around the guide. Applying penetrating oil can aid the process, especially on stubborn guides. For particularly tight fits, gentle heating of the cylinder head around the guide can assist, but excessive heat must be avoided to prevent warping.

Another technique employs a pneumatic valve guide removal tool, offering controlled force and minimizing the risk of damage. Regardless of the method, support the cylinder head adequately during the process to prevent bending or cracking. Careful attention and the correct tools are paramount for successful valve guide removal.

Valve Guide Installation Procedures

Proper valve guide installation is critical for maintaining engine performance and preventing future issues. New guides are often installed using a specialized installation tool, ensuring they are seated squarely and to the correct depth within the cylinder head. Before installation, chill the new guides in a freezer; this slightly shrinks them, facilitating a tighter fit;

Apply a light coating of assembly lube to the guide’s outer surface to aid installation and prevent galling. Gently press the guide into place, using even pressure to avoid tilting. Avoid hammering directly on the guide, as this can cause damage.

After installation, verify the guide’s height is correct relative to the valve seat. Accurate installation ensures proper valve alignment and sealing, contributing to optimal engine operation and longevity.

Reaming and Honing Valve Guides

Following valve guide installation, reaming and honing are often necessary to achieve the correct valve stem-to-guide clearance. Reaming enlarges the guide’s inner diameter to ensure smooth valve movement without excessive play. This process requires precision to avoid over-sizing, which can lead to oil leakage and valve instability.

Honing follows reaming, refining the surface finish and creating a precise, consistent bore. Specialized honing tools utilize abrasive stones to remove material gradually, achieving the desired clearance. It’s crucial to use the correct honing stone grit and maintain consistent pressure.

Regularly check the clearance with a precision measuring tool throughout the process, aiming for the manufacturer’s specified tolerances. Proper reaming and honing are vital for optimal valve function.

Preventative Maintenance for Valve Guides

Regular oil changes, clean air filters, and proper engine tuning are essential for minimizing valve guide wear and maximizing engine lifespan and performance.

Regular Oil Changes

Consistent and timely oil changes are paramount for maintaining healthy valve guides. Clean oil effectively lubricates the valve stems as they move within the guides, significantly reducing friction and wear. Over time, oil degrades and accumulates contaminants – including abrasive particles – that can score the valve guide surfaces.

These particles act like sandpaper, accelerating wear and potentially leading to excessive valve guide clearance. Using the correct oil viscosity and specification, as recommended by the engine manufacturer, is also crucial. Synthetic oils often provide superior lubrication and protection compared to conventional oils, further extending valve guide life. Neglecting oil changes allows harmful deposits to build up, compromising the valve guide’s integrity and ultimately impacting engine performance and efficiency.

Air Filter Maintenance

A properly maintained air filter is surprisingly vital for valve guide health. A dirty or improperly fitted air filter allows abrasive particles – dust, dirt, and debris – to enter the engine’s combustion chamber. These particles don’t just affect cylinder walls; they can also find their way past the valve seals and into the valve guide area.

Once lodged between the valve stem and guide, these contaminants act as grinding compounds, accelerating wear on both components. This is particularly common with intake valve seat wear. Regularly inspecting, cleaning (if reusable), or replacing the air filter according to the manufacturer’s recommendations prevents this abrasive damage. Ensuring a tight seal around the air filter housing is equally important to avoid bypass and protect the entire engine, including the valve guides.

Proper Engine Tuning

Engine tuning significantly impacts valve guide longevity. Incorrect fuel-air mixtures can lead to incomplete combustion, creating excessive heat within the cylinders. This elevated temperature stresses all valve train components, including the valve guides, accelerating wear and potential failure. Lean mixtures, in particular, generate higher combustion temperatures, exacerbating the problem.

Properly timed ignition and valve events are also crucial. Incorrect timing can cause valve overlap issues, leading to increased stress on the valve guides. Regular engine diagnostics, including checking for proper combustion and timing, are essential preventative measures. Maintaining the engine within its designed operating parameters minimizes stress and extends the lifespan of the valve guides, ensuring optimal performance and reliability.